April 3-4 2024 Omaha NE “Hands-On” Precision Gage Calibration and Repair Training

Event Date:

April 3, 2024

Event Time:

8:30 am

Event Location:

TBD

Calibration & Repair Workshop.

This is an in-person, public, 2-day, “Hands-On” Precision Gage Calibration and Repair Training.

IICT is your #1 source to meet your calibration training requirements for:

- ISO 9000

- ISO 13485

- AS 9000, and

- IATF 16949 Certification.

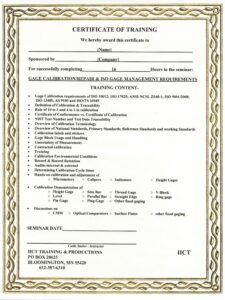

Certificates are presented immediately upon successful completion of the course.

Join me for a 2-Day “Hands-On” Precision Gage Calibration & Repair Workshop. This training will last 14-16 hours and will cover the following goals and topics:

This 2-day online precision gage and repair training offers specialized training in calibration and repair for the individual who has some knowledge of basic Metrology. Approximately 75% of the workshop involves “Hands-on” calibration, repair, and adjustments of micrometers, calipers, indicators, height gages, etc. The course covers NIST Traceability, Certificates of Conformance, Gage Management, Standards, etc.

Each student is encouraged to participate in actual calibrations and repairs. A list of gages used in the class is available from Carlis at iict@msn.com.

Goal

- Equip attendees with the knowledge to meet current and future calibration needs

- Leave this class prepared to save your company money on calibrations

- Provide attendees opportunities for personal growth in the Quality Field

TOPICS COVERED IN THIS In-Person Calibration/Repair Training:

- Calibration Requirements of ISO 17025, ISO 13485,

ANSI-NCSL Z540-1, 1994, ISO 9001, IATF16949, ISO 10012.

- Definition of Calibration & Traceability.

- Rule of 10 to 1 and 4 to 1.

- Certificate of Conformance vs. Certificate of Calibration.

- NIST Test number and Test Date-Traceability.

- Overview of Calibration Terminology.

- Summary of National, Primary, Reference, and Working Standards.

- Calibration labels and stickers.

- Gage Block Usage and Handling.

- Determining Calibration cycle times.

- “Hands-on” Calibration Methods of;

- Micrometers °Calipers °Indicators °Sine bars

- Levels °Thread gages °Pin Gages

- Plug Gages °Squares °Height Gages

- Scales Other Gages as customer requests

- Discussion on Optical Comparators, Surface Plates, Ring Gages, CMMs, etc

- “Hands-on” Repair techniques of Micrometers, Calipers, and Dial Indicators

TOPICS COVERED

- ISO-10012:2003 Related Standards

- Certificate of Conformance vs. Certificate of Analysis

- National Institute of Standards and Technology

- Which Systems Need to Be Calibrated, Controlled, or Verified in a Measurement System

- Qualifications to Calibrate Systems & Document Procedures

- Choosing the Proper Equipment

- Three Elements: Capability, Traceability, Reliability

- Maintaining Traceability

- Why Registration to a Quality Management System Is Not Sufficient

- How Software Affects Your Calibration System

- Using Outside Calibration Services

- Hands-on calibration, repair, and adjustments of Micrometers, Calipers, Indicators, and Height Gages (this comprises approximately 75% of the total class time)

- Gage Calibration requirements of ISO 10012; ISO 17025; ANSI-NCSL Z540-1; ISO 9001:2000 and ISO/TS 16949; ISO 13485

- Definition of Calibration & Traceability

- Rule of 10 to 1 and 4 to 1 in calibration

- Certificate of Conformance vs. Certificate of Calibration

- NIST Test Number and Test Date Traceability

- Overview of Calibration Terminology

- Overview of National Standards, Primary Standards, Reference Standards, and Working Standards

- Calibration Labels and stickers

- Gage Block Usage and Handling

- Uncertainty of Measurement

- Contracted calibration

- Training

- Calibration Environmental Conditions

- Record & Record Retention

- Audits-internal & external

- Determining Calibration Cycle times

- “Hands-On” Student participation calibrating and repairing micrometers, calipers, and indicators (not test)

- “Hands-On” Student participation calibrating Thread, Plug, Pin, and Ring Gages; Sine Bars; Levels; V-blocks; Height Gages, and other hard gaging as requested

- Discussions regarding calibrations of CMM, Optical Comparators, Surface Plates, and other equipment, as requested.

Certificate of Training is provided following successful completion of the class.

Goal

Completing this Calibration/Repair Training will meet the following goals.

- Equip attendees with the knowledge to meet current and future calibration needs

- Leave this class prepared to save your company money on calibrations

- Provide attendees opportunities for personal growth in the Quality Field

CANCELLATION POLICY

Suppose circumstances beyond our control require IICT to cancel or postpone a. In that case, IICT cannot be held responsible for canceled airfares, canceled hotels, or any other expenses incurred by the student due to the cancellation of the course. We reserve the right to cancel or reschedule any event or to change instructors.

-

- The workshop registration fee is refunded up to 21 days before the workshop, less a $100 fee.

- No refunds within 21 days of the workshop. Substitutions are allowed at any time.

- A registrant or substitute from the same company may attend a class later.

LINKS

https://calibrationtraining.com/procedures/